Step-Up / Step-Down Transformers: A Smarter Way to Tackle Long Cable Runs

When customers ask about long cable runs—say, hundreds of metres from a generator or switchboard to remote equipment—one of the first concerns is voltage drop and the cost of heavy-duty cabling. And they’re right to be concerned: oversized cable to carry 415V over long distances can be a major budget killer.

A Smarter Option: Step Up to 1000V, Then Step Down Again

One often-overlooked solution is the use of a step-up / step-down transformer system. The principle is simple, yet powerful:

- Step up the voltage from 415V to 1000V at the source using a transformer

- Run thinner, more affordable cable over the long distance

- Step back down to 415V at the load end using a second transformer

By increasing the voltage, you reduce the current needed to transfer the same amount of power. And because cable cost and size are primarily driven by current (not voltage), the savings can be significant. Less current means thinner cable, simpler installation, and often fewer headaches with voltage drop and compliance.

A Real-World Example

At SES, we recently delivered a 200kVA step-up / step-down transformer solution for a customer facing this exact challenge. The system was designed to step 415V up to 1000V, transmit it across a long run, then step it back down to 415V again for local use.

Each transformer handled:

- 415V @ 288A ➜ 1000V @ 115A (and vice versa)

- Electrostatic screens for noise suppression and added fault protection

- ±2.5% & ±5% tap settings to fine-tune voltage and account for distance or load variation

- IP65 enclosures for full outdoor weather protection

This approach allowed the customer to drastically reduce cable size and cost—while still delivering safe, stable power over a long run.

When It’s Worth It… And When It’s Not

If Transformers Are Installed Indoors (or Under Cover)

The economics of this approach become especially attractive when transformers can be installed in IP23-rated enclosures, typically used for indoor or protected locations.

Customers can often house the transformers in existing buildings, shipping containers, or even prefab sheds under $1,000. When this is possible, the cost of the transformer system is usually offset—sometimes many times over—by the cable savings and installation ease.

If IP65-Rated Outdoor Transformers Are Required

However, when the transformers need to be installed in exposed environments, costs rise quickly due to:

- Fully sealed mild steel or stainless-steel enclosures

- IP66-rated wiring chambers and connection points

- Weatherproof glands, ventilation, and anti-corrosion coatings

In these cases, the transformer system might end up more expensive than simply using larger cable—if that’s even feasible.

When Cable Just Isn’t an Option

Some projects don’t just prefer a transformer-based approach—they demand it.

Take our recent project with TASSAL, Australia’s largest aquaculture company. They needed to deliver power from the shore to offshore fish-feeding barges in Port Arthur, Tasmania. Trenching or running oversized cable underwater wasn’t practical—or affordable.

Our 200kVA step-up / step-down system enabled power to be stepped up onshore, transmitted via thinner underwater cabling, and then stepped back down on the barge. It eliminated the need for diesel generators, slashing emissions and fuel costs. The system is now saving TASSAL millions annually.

Other ideal use cases include:

- Mountainous terrain where cable runs are physically difficult or expensive

- Remote or offshore locations where trenching or conduit access is restricted

- Environmentally sensitive areas where excavation is tightly regulated

The Key Takeaway

Transformer-assisted cable runs are a highly effective solution when the conditions are right.

If your site has long distances, limited cable access, or existing shelter structures, the savings can be substantial. But if the only option is outdoor-rated transformers in exposed locations, it’s worth running a proper cost-benefit analysis.

Either way, it’s a conversation worth having early in the design process.

Need Help With Your Setup?

At Southern Electronic Services, we design and manufacture step-up and step-down transformer systems for industrial, marine, off-grid, and commercial applications across Australia. Whether you need 10kVA or 750kVA, our team will help you weigh up the transformer vs. cable cost tradeoff and tailor the right solution for your site.

Contact us today to start a conversation.

step down transformer, transformer, 3 phase, stepdown transformer, 3ph equipment, convert voltage, Step Up transformer

Get the Latest in Power Transformer Solutions

Get industry insights, product updates, and exclusive offers

Any More Questions?

To help us provide you with the best solution to your needs please contact us

Next Post

What does an Isolation Transformer actually Do?

June 13, 2025Other News

The Lifecycle of a 3 Phase Transformer

3-phase transformers are incredibly useful; they allow businesses to distribute power efficiently, safely, and reliably across large or complex systems. By converting voltage levels and balancing electrical loads, they help machinery run smoothly, reduce energy losses, and prevent costly downtime. But how do they work, and what can you expect from their lifecycle? In this…

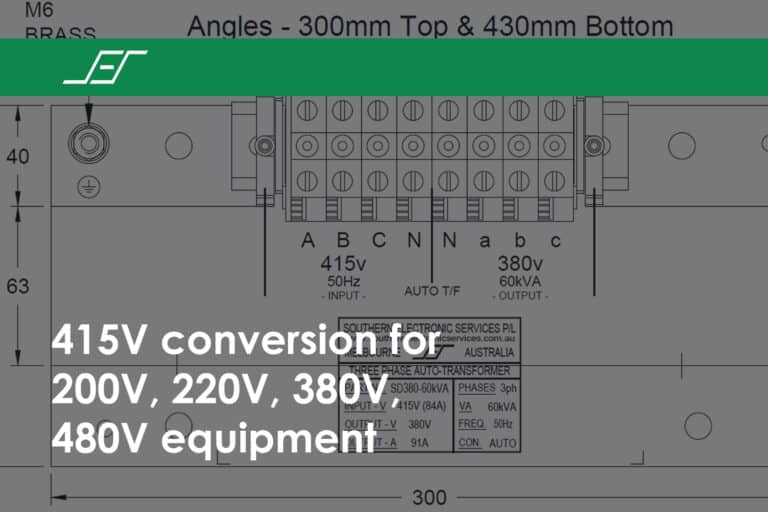

3-Phase Transformer 415V Conversion | 200V, 220V, 380V, 480V

Powering Global Equipment Locally: SES’s Recent 3-Phase Auto 415V Conversion Solutions With global availability to electrical equipment, but need to run the machinery in Australia, you require a 415V conversion solution. When global machinery meets local power conditions, compatibility is key. At Southern Electronic Services, we specialise in 3-phase step-down auto transformers that bridge voltage…