Ever used, or specified, an isolation transformer… but not been 100% sure why?

You’re not alone. Ask five different people why, and you’ll get five different answers. Let’s clear it up.

Isolation transformers are often specified, but rarely understood, and potentially unnecessary.

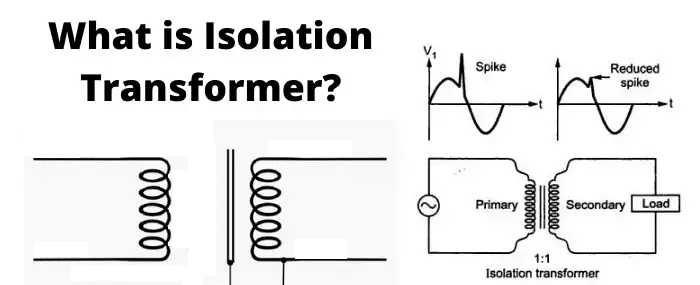

At their core (pun 100% intended), they provide galvanic isolation, physically separating the input and output windings so there’s no direct electrical connection between the source and the load.

But what does that actually mean for your system?

What, When, and Why?

What:

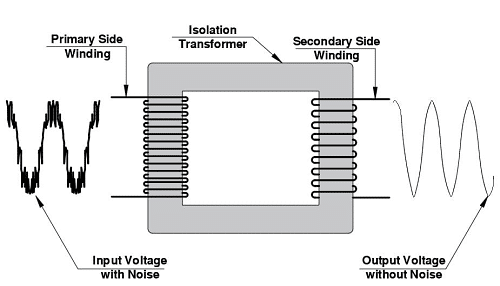

Isolation Transformers prevent unwanted current paths and reduce risks from ground loops, harmonics, or spikes coming from upstream.

When energised, the primary winding generates a magnetic field in the transformer’s steel core. This field induces voltage in the secondary winding, without any direct electrical connection between the two. This principle of galvanic isolation is what allows power to transfer while keeping input and output electrically separated. This physical separation helps eliminate unwanted current paths, ground loops, and electrical noise, making it ideal for sensitive or isolated systems.

When:

- Installing VSDs or sensitive equipment

- Creating a new, clean earth reference (e.g. IT (Isolated Terra) earthing)

- Marine, mining, or off-grid systems

- Interfacing multiple supplies

- Anytime you want a cleaner, safer, more stable power supply

Why?

- They improve system safety and fault tolerance

- Help avoid nuisance RCD tripping

- Suppress electrical noise

- Comply with IT (Isolated Terra) earthing or isolation requirements

Where it makes a difference

We’ve supplied isolation transformers for hundreds of complex or remote projects. A few examples:

Distributed Power Systems

BESS, Standalone power systems (SPS) & grid applications

To shield sensitive loads from upstream noise, voltage spikes, and harmonics common in renewable, remote, or battery-fed systems.

Learn more – stand-alone power systems

Heavy industrial loads

Mining, Dragline excavators, tough electrical environments

Drive isolation transformers are critical to handle extreme harmonic content and protect supply equipment from feedback stress.

Learn more – SES transformers & Mining

Data centres, UPS systems & critical infrastructure:

Cloud storage, Data Security, UPS Integration & Bypass

To ensure clean, reliable power for sensitive systems, eliminate ground loops, and maintain uptime where failure isn’t an option.

Learn more – Date centre Projects

Harmonic-rich electrical systems systems:

VFD’s / VSD’s, motor-drive systems

To limit common-mode noise, protect motor drives, and improve system reliability, especially in HVAC, manufacturing, and pharma.

Learn more – Isolation transformers & VSD’s

When NOT to use one

- There’s already a transformer upstream

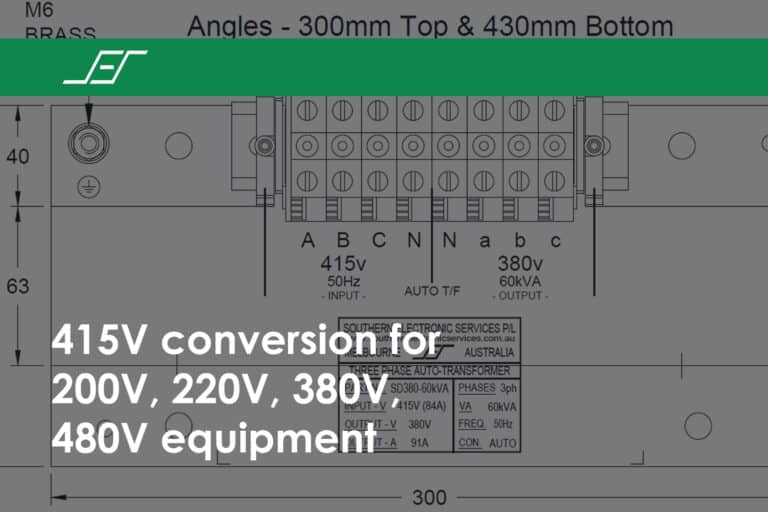

If your site’s main switchboard or existing infrastructure already provides adequate isolation, adding another isolation transformer is usually unnecessary. - You only need to convert voltage

For example, if you’ve purchased a piece of equipment from overseas that runs on 380V instead of 415V, you likely just need an autotransformer (technical name for a voltage converting transformer); you don’t actually need full galvanic isolation.

In around 95% of these cases, a 3-phase autotransformer is the better option. Autotransformers convert voltage efficiently, but do not isolate input and output. They’re also typically smaller, more cost-effective, and simpler to install than isolation transformers.

Want to understand the difference?

Read more about Auto vs Isolation transformers

Need a step-down solution?

View our 3-phase step-down transformer range

Remember: Isolation sounds better and safer, but it’s not always the right call. Knowing when to use one (and when not to) can save your project thousands.

Get the Latest in Power Transformer Solutions

Get industry insights, product updates, and exclusive offers

Any More Questions?

To help us provide you with the best solution to your needs please contact us

Next Post

VSDs & Isolation Transformers - What / When / Why

May 19, 2025Other News

The Lifecycle of a 3 Phase Transformer

3-phase transformers are incredibly useful; they allow businesses to distribute power efficiently, safely, and reliably across large or complex systems. By converting voltage levels and balancing electrical loads, they help machinery run smoothly, reduce energy losses, and prevent costly downtime. But how do they work, and what can you expect from their lifecycle? In this…

3-Phase Transformer 415V Conversion | 200V, 220V, 380V, 480V

Powering Global Equipment Locally: SES’s Recent 3-Phase Auto 415V Conversion Solutions With global availability to electrical equipment, but need to run the machinery in Australia, you require a 415V conversion solution. When global machinery meets local power conditions, compatibility is key. At Southern Electronic Services, we specialise in 3-phase step-down auto transformers that bridge voltage…